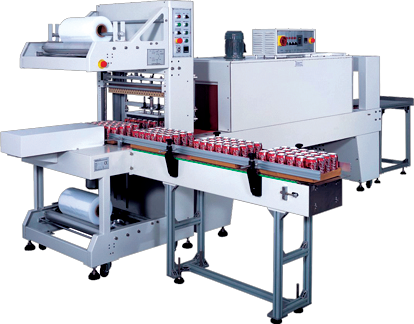

Fully automatic cuff packing machine

Cuff packaging Machine is the use of monolithic double-roll PE film, first through the cutting machine cut knife seal into a cylindrical, that is, cuff shape and wrap the product, and then horizontal into the automatic cuff type heat shrinkage packaging machine after heating, so that PE shrinkage film shrinkage wrap tightly wrapped products or packaging parts, and left and right ends into a circular cuff shape, convenient handling. This is known as the cuff type automatic heat shrinkage packaging machine.

Device Features:

1, the use of international advanced control components, stable and durable performance;

2, sealing knife using special design, sealing firm, non-cracking, non-stick knife;

3, automatic feed, whole column, push material, film delivery, sealing;

4, infinitely mechanical speed regulation, adjust the feed conveyor belt speed;

5, according to the requirements of 2 rows, 3 rows, 4 rows and other bottom bracket of a number of combination packaging, replacement packaging mode through the Control Panel conversion switch can be completed;

6, easy to operate, simple, replacement of different specifications 2-3 minutes can be completed;

7, according to different bottle type, design automatic feeding device;

8, Feed conveyor belt direction can be based on customer needs, design for the left feed or right feed mode;

9, the application of PE shrinkage film;

Packaging size:w+H ≤700mM / (LxWxH) 1500x550x330mM

Production capacity:20~60pcs/miN

Knife RulerInchFurnace Cavity Size:700mM / (LxWxH) 1800x600x400mM

ElectricSourcePower:220V/380V50HZ/60HZ22KW

贝立智能

贝立智能

浙公网安备 33011002012462号

浙公网安备 33011002012462号