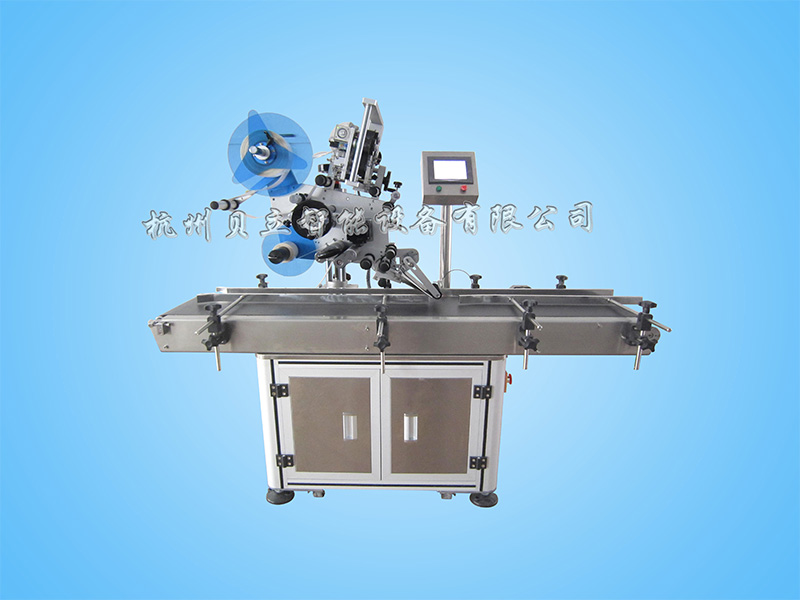

We often use labeling machine when the problem of labeling accuracy is poor, labeling accuracy is very easy to affect the aesthetics of the label, so there is such a problem to adjust in a timely manner. So is those reasons to incur labeling machine labeling accuracy is poor? And how should it be adjusted? Now we're going toFully automatic flat labeling machineIllustrated as an example.

Generally speaking, the labeling machine appears the condition of poor precision, there are three main categories of reasons:

First of all, for mechanical reasons.

Mechanical reasons are divided into static and dynamic two kinds:

A. Static reasons for the performance of the header shaking, treatment method: After fastening the head and adjust the fixed seat, so as to reach the fixed head, thus preventing shaking.

B. Detailed reasons for the dynamics: 1. The product is shaking on the warranty, treatment method: After reducing the guide gap, so as to prevent the product from shaking on the protection; 2. Marking and product speed matching, processing method: After adjusting the traction frequency or the speed of the conveyor, so that the product arrived at the labeling position when the right out of the label.

Category II, electrical reasons

Electrical reasons include both detection and power:

A. Detailed reasons for testing are: 1. Stoppage, treatment method: Reset the marking electric eye, so that the labeling machine in the product labeling after the suspension of the bid; 2. The measurement is not allowed, treatment method: Adjust the measuring electric eye and amplifier, can be accurately detected with labeling products, and accurate marking.

B. The common cause of power is the abnormal transmission, the treatment method: After checking and fastening the transmission parts, to ensure the normal operation of the labeling machine.

Category III, product reasons

There are two reasons for the product, such as labels and products:

A. Problems with labels Common label spacing is not up to standard, processing method: Select the label spacing to meet the standard stop labeling.

B. Problems with products there are common product accuracy errors, treatment methods: Check the adjustment of product size accuracy, to ensure that labeling when the label affixed to the fixed position of the product.

Related Industry Knowledge

- What are the common faults of automatic labeling machine equipment?

- Describe in detail what is called Automatic sealing machine

- Application of automatic palletizing machine in injection molding industry

- What are the benefits of pasting in a small labeling machine

- Do you know what the criteria are for choosing a semi-automatic filling machine?

- How to maintain the semi-automatic filling machine correctly

- Take you to understand how a fully automated labeling machine Works

- How to operate the sealing machine correctly

- How to maintain and maintain the set of marking machine

贝立智能

贝立智能

浙公网安备 33011002012462号

浙公网安备 33011002012462号