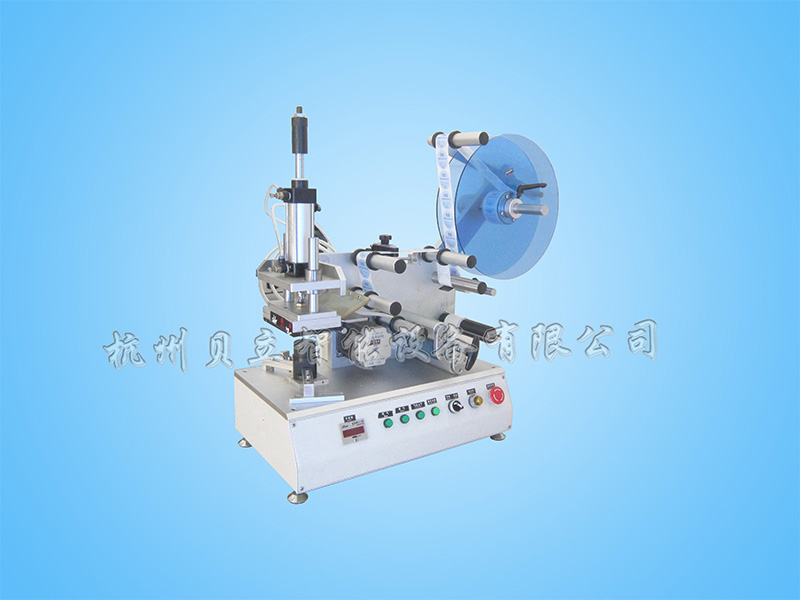

Semi-automatic flat labeling Machine

Basic use:

The use of suction paste method labeling, to achieve in a variety of workpieces on the plane labeling, such as cosmetic flat bottles, packaging boxes, plastic product labeling and so on.

Change the labeling mechanism, can be applied to uneven surface labeling, such as concave plane, small arc surface labeling and so on.

Change the fixture, which can be applied to the labeling of various irregular workpieces.

Optional ribbon coding machine or inkjet machine, print production date and batch number on the label, achieve code-Labeling integration.

Scope of application:

* Applicable Tags: non-dry glue labels, non-dry film, electronic regulatory code, bar code, etc.

* Applicable products: required inPlane, small arc surface, circumference, concave surface, convex surface, or other polygonsTagged products;

* Application industry: Widely used in cosmetics, food, toys, daily, electronics, medicine and other industries;

* Application Examples: Shampoo flat bottle labeling, box labeling, bottle cap, plastic shell labeling and so on.

Feature Features:

* Powerful, this automaticPlane Labeling MachineCan be used for a variety of workpieces of the plane, arc surface, concave plane labeling; can be used for irregular workpiece labeling.

* Accurate labeling, high stability, the use ofplc+ Subdivision Stepper Motor Drive marking, accurate delivery, discharge mechanism to configure braking function, to ensure that the marking belt taut, to ensure that the label detection is accurate, tape bypass correction mechanism, to prevent the label left and right offset.

* Long durable, circuit and gas separation arrangement, gas Road configuration purification device, to avoid air moisture infringement electrical appliances, extend the life of equipment, the whole machine using high-end aluminum alloy and stainless steel materials, solid quality.

* Easy adjustment, configuration of high and low stroke adjustable function, different height product labeling, no need to repeatedly replace the fixture.

* Has automatic/automatic 2 kinds of labeling control mode, workers can choose to use sensors or feet to achieve the control of labeling according to their needs, set up manual, Automatic control button, the length of the mark can be arbitrarily regulated.

* Optional Features and components:① Hot Code/Spray code function ② Automatic feeding function ③ automatic feeding function (combined with product consideration) ④ special label Electric Eye.

Operating instructions:

*Core working principle: the sensor detects the product in place or the foot to send out the product in place signal, suck the label of the suction head downlink labeling and overlay, and then return to the in situ adsorption of the next label, waiting for the next labeling signal, a label attached to the action to complete.

* Operation Process: Release product—>Determine in place (equipment inspection control or manual control)->Labeling and labeling (automatic realization of equipment)->Remove the labeled product.

Technical parameters:

The following are standard Model technical parameters, other special requirements and functions, can be customized.

* Labeling accuracy:±0.5mm (excluding product, label error);

* Labeling Speed:20~30 pieces/min (related to product, label size);

* Applicable Product size:20≤Length≤200mm,20≤Width≤200mm;

* Applicable label Size:20≤Length≤100mm,20≤Width≤120mm;

* Machine Size:600x370x700mm (length × width × height);

* Applicable power supply:220V 50/60HZ;

* Weight of the whole machine:41Kg。

贝立智能

贝立智能

浙公网安备 33011002012462号

浙公网安备 33011002012462号