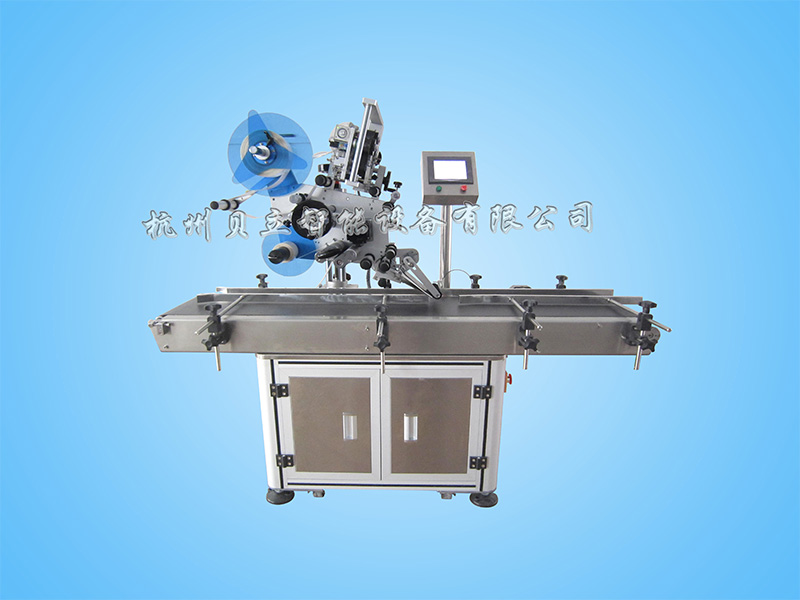

Fully automatic flat labeling machine

Basic use:

Fully automatic flat labeling machineApplicable to a variety of items on the plane label or non-dry film, such as books, folders, boxes, cartons, etc., the replacement of the marking mechanism can be applied to uneven surface labeling, widely used in culture and education, medicine, cosmetic plane, small arc surface, groove labeling.

Optional coding machine or inkjet machine to the sticker head, you can print on the label production date, batch number and printing bar code and other information.

Optional inkjet machine to conveyor belt, can achieve pre-labeling or labeling after the product printing production date, batch number, barcode and other information.

Scope of application:

* Applicable Tags: adhesive labels, non-dry film, electronic regulatory Code, barcode and so on.

* Applicable products: products that require labels or membranes to be attached to a flat, large radian surface.

* Application industry: Widely used in printing, stationery, food, daily, electronics, medicine, and other industries.

* Application Examples: Book flat labeling, folder labeling, packaging box labeling, plate labeling and so on.

Feature Features:

* Wide range of application to meet product width30~350mm product plane labeling and non-dry film, replacement of the labeling mechanism can meet uneven surface labeling.

* Labeling accuracy is high, subdivision stepper motor or servo motor drive delivery standard, accurate delivery, standard belt bypass correction mechanism design, to ensure that the label traction process is not left or right offset; eccentric wheel technology applied to traction mechanism, traction label does not slip, to ensure that the markingAccurate.

* Rugged and durable, the use of three-bar adjustment mechanism, make full use of the stability of the triangle, the machine is solid and durable.

* High stability, Panasonicplc+ Panasonic touch screen + Panasonic needle-shaped electric eye + German Labor Easy label Electric Eye composed of high-end electronic control system, support equipment 7x24 hours operation.

* Simple adjustment, design6 degrees of freedom adjustable adjustment seat, conversion between different products become simple, time-saving.

* Flexible application, can be single-machine production or assembly line production, production site layout is simple.

* Intelligent control, automatic photoelectric tracking, with nothing without labeling, non-standard automatic correction and label auto-detection function, to prevent leakage stickers and label waste.

* Touch screen operation interface, full Chinese annotation and perfect fault prompt function, all kinds of parameter adjustment is simple and fast, easy to operate.

* Powerful, with production counting function, power saving function, production number setting prompt function, parameter setting protection function, convenient production management.

* Optional Features and components:① Thermal Coding/Inkjet function ② automatic feeding function (combined with product consideration) ③ automatic feeding function (combined with product consideration) ④ increase labeling device ⑤ other functions (customized according to customer requirements).

Operating instructions:

* Core working principle: the sensor detects the product passing, returns the signal to the labeling control system, and the signal passes through thePLC treatment, in the appropriate time to send out the label attached to the product setting position, the product flows through the cladding device, the label is firmly covered, a label attached to the action to complete.

* Operation Process: Release product (can be connected to the assembly line)-> Product Delivery (automatic realization)-> Product correction (automatic realization)-> Product detection (Automatic implementation)-> labeling (Automatic implementation)-> Overlay (Automatic implementation)-> collection of tagged products.

Technical parameters:

The following are standard Model technical parameters, other special requirements and functions, can be customized.

* Labeling accuracy:±1mm (excluding product, label error);

* Labeling Speed:20~180 pieces/min (related to product, label size);

* Applicable Product Size: Width30~350mm, length≥20mm, Height≤350mm;

* Applicable label Size:15≤ width ≤200MmLength≥20mm;

* Machine Size:1800x700x1550mm (length × width × height);

* Applicable power supply:220V 50/60HZ;

* Weight of the whole machine:180Kg。

贝立智能

贝立智能

浙公网安备 33011002012462号

浙公网安备 33011002012462号