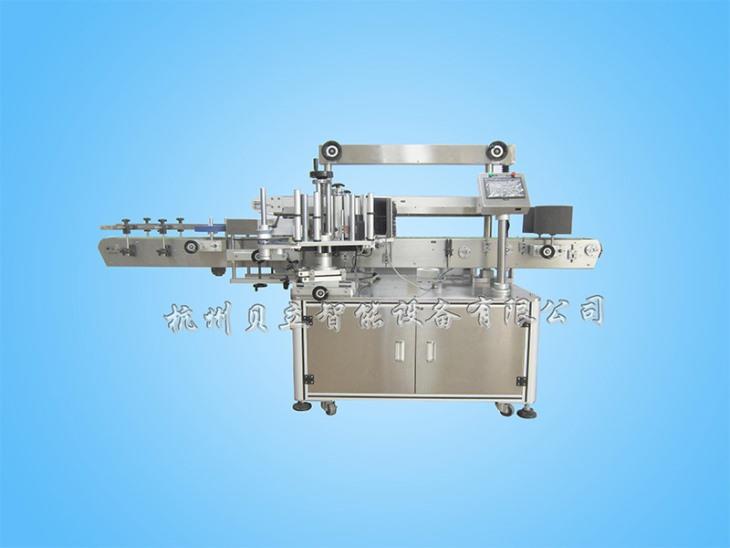

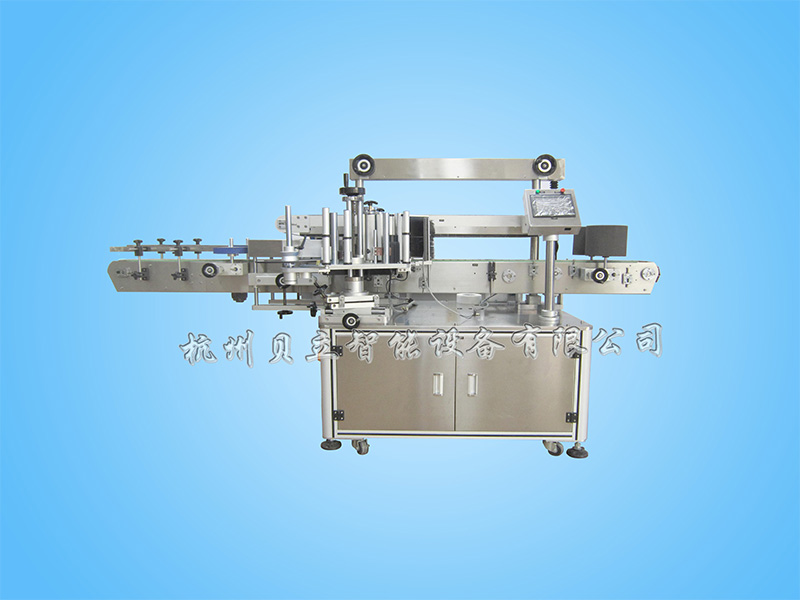

Fully automatic double side labeling Machine

Basic use:

Suitable for flat bottles, round bottles, square bottles of single-sided and double-side labeling, such as shampoo flat bottle, lubricating oil flat bottle, hand sanitizer round bottle and other double side labeling, two sides of the same sticker, double standard to improve production efficiency, widely used in daily, cosmetics, petrochemical, pharmaceutical and other industries.

Optional ribbon coding machine and inkjet machine, to achieve on the label printing production date and batch number information, the implementation of labeling-Assign code integration.

Optional assembly line Inkjet machine, the implementation of pre-labeling and labeling after the printing of product information on the product.

Scope of application:

* Applicable Tags: non-dry glue label, non-dry film, electronic supervision Code, barcode, etc.

* Applicable products: required in the side plane, side large radian surface, circumference surface affixed with the label of the product;

* Application industry: Widely used in cosmetics, daily, electronics, medicine, hardware, plastics and other industries;

* Application Examples: Shampoo flat bottle labeling, lubricating oil flat bottle labeling, shampoo round bottle labeling and so on.

Feature Features:

* Powerful, one machine can achieveSingle-sided and double-sided labeling of 4 products (round bottles, flat bottles, square bottles, special-shaped bottles).

* The use of two-sided rigid plastic synchronous guide chain, automatically ensure that the bottle to neutral, the worker bottle and assembly line docking bottle requirements are low, greatly reduce the worker's work or assembly line docking difficulty, can be single-machine production, can also be connected to the assembly line production.

* Configuration of elastic pressure-type topstone mechanism to ensure smooth delivery of products, and effectively eliminate the bottle height of its own error.

* Configure automatic bottling mechanism to automatically separate spacing before guide bottle to ensure the stability of subsequent guide bottle, conveyor and labeling.

* Configuration of two-fold labeling mechanism, the initial guarantee of labeling accuracy, two extrusion marking, effectively eliminate bubbles and ensure that the label at the end of the clamp.

Operating instructions:

*Core working principle: this kind of fullAutomatic Labeling MachineSensor detection of the product through, return signal to the labeling control system, in the appropriate position control system control motor delivery label and affixed to the product to be labeled position, the product flows through the cladding device, label overlay attached to the product, a label attached to the action to complete.

* Operation Process: Release product (can be connected to the assembly line)—>Product Spacing->Product Orientation and Topstone->Product Topstone Conveyor->Product Testing->Labeling->Overlay->Collect labeled products.

Technical parameters:

The following are standard Model technical parameters, other special requirements and functions, can be customized.

* Labeling accuracy:±1mm (excluding product, label error);

* Labeling Speed:40~180 pieces/min (related to product, label size);

* Applicable product size: Flat bottle/Square Bottle: Width≥20mmLength≥20mm,30≤Height≤350mm;

Round bottle/cone bottle: ¢20≤Diameter≤¢120mm,30≤Height≤350mm

* Applicable label Size:15≤ width ≤200MmLength≥10mm;

* Machine Size:2300x1500x1550mm (length × width × height);

* Applicable power supply:220V 50/60HZ;

* Weight of the whole machine:250Kg。

贝立智能

贝立智能

浙公网安备 33011002012462号

浙公网安备 33011002012462号