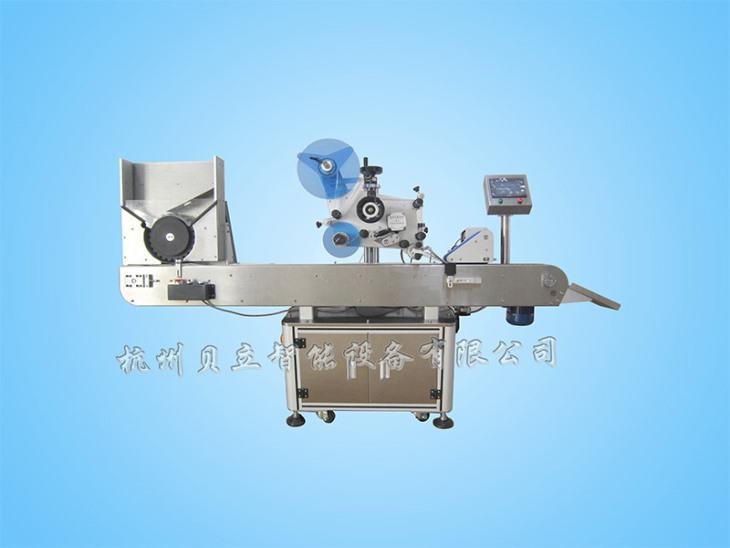

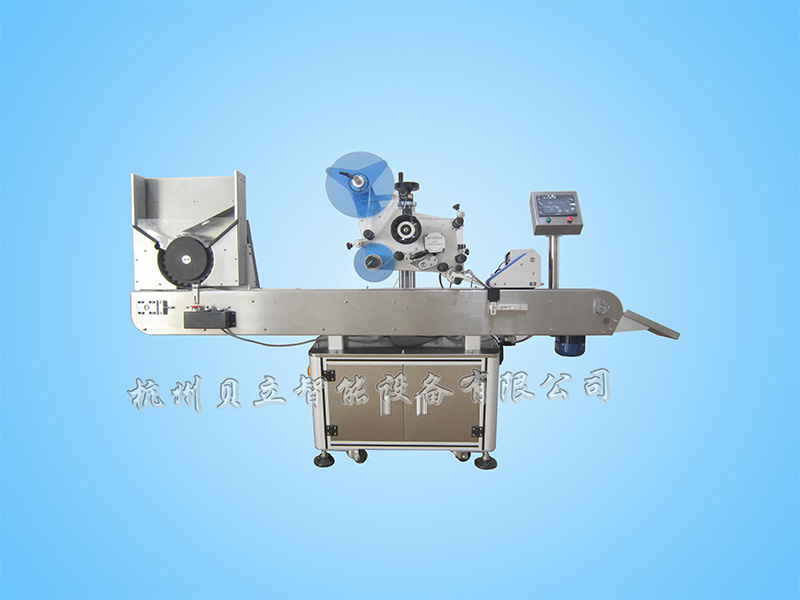

Automatic horizontal round bottle labeling Machine

Basic use:

Suitable for the circumferential and semi-circular labeling of small cylindrical objects standing unsteady, the method of horizontal transmission and horizontal labeling is used to increase stability and improve the efficiency of labeling.

Optional coding machine or inkjet machine to the sticker head, you can print on the label production date, batch number and printing bar code and other information.

Optional inkjet machine to conveyor belt, can achieve pre-labeling or labeling after the product printing production date, batch number, barcode and other information.

Scope of application:

* Applicable Tags: adhesive labels, non-dry film, electronic regulatory Code, barcode and so on.

* Applicable products: Requires small products with labels or membranes attached to the circumference or small cone surface.

* Application industry: Widely used in medicine, cosmetics, electronics, hardware, plastics and other industries.

* Application Examples: solid rubber bottle labeling, oral liquid bottle labeling, pen labeling, lipstick labeling and so on.

Feature Features:

* High-speed, the use of side-side drum conveyor mechanism, conveyor chain tilt, bottle Automatic guide, conveying labeling stability. Labeling speed up to300 bottles/min, saving a lot of manpower and material resources.

* Labeling quality is excellent, the use of standard belt bypass correction technology, label head and tail to paste overlap is high, rubbing rolling overlay, labeling flat, no wrinkles, no bubbles, improve the quality of packaging.

* Intelligent control, automatic photoelectric tracking, with nothing without labeling, non-standard automatic correction and label auto-detection function, to prevent leakage stickers and label waste.

* With fault alarm function, production counting function, power saving function, production number setting prompt function, parameter setting protection function, convenient production management.

* Optional Features:① Hot Code/Spray code function ② Automatic feeding function (combined with product consideration) ③ automatic feeding function (customized according to customer requirements).

Operating instructions:

* Core working principle: the bottle wheel will be separated from the product, put on the conveyor belt, the sensor detected the product through, send back the signal to the labeling control system, in the appropriate position control system control the corresponding motor to send out the label and affixed to the product to be labeled position, the product flows through the cladding device, the cladding belt drive the product rotation, The attached action of a label is completed.。

* Operation Process: Put the product (placed in the drop box)-> separate products and spread out to the center of the conveyor chain drum-> Product Delivery-> Product Testing-> Labeling-> Overlay-> Collection of labeled products.

Technical parameters:

The following are standard Model technical parameters, other special requirements and functions, can be customized.

* Labeling accuracy:±0.5mm (excluding products, label errors);

* Labeling Speed:100~320 pcs/min (related to product, label size);

* Applicable product size: diameter9~25mm;

* Applicable label Size:10≤ width ≤100MmLength≥15mm;

* Machine Size:1600x650x1550mm (length × width × height);

* Applicable power supply:220V 50/60HZ;

* Weight of the whole machine:220Kg。

贝立智能

贝立智能

浙公网安备 33011002012462号

浙公网安备 33011002012462号