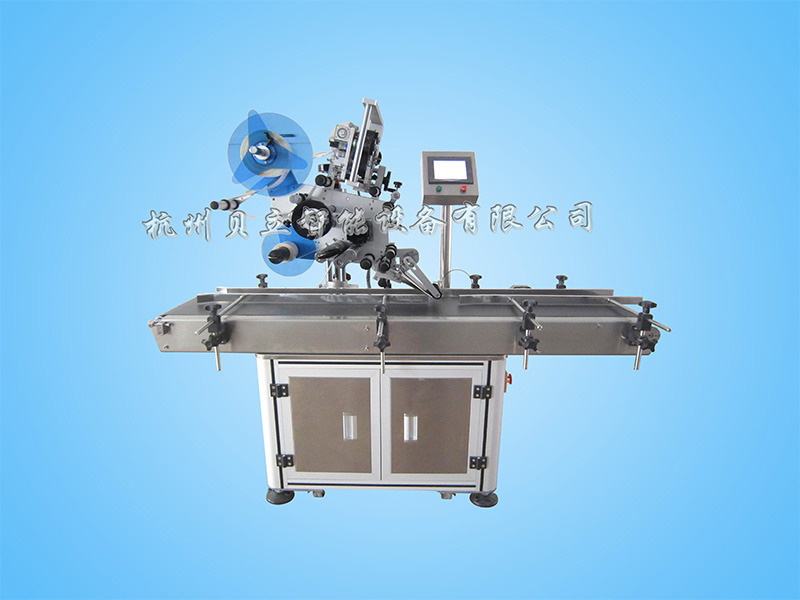

Plane labeling machine is an ideal equipment for fast and automatic labeling on round bottle products in food, medicine, cosmetics and other light industry. It is affordable and compatible. It can be equipped with laser machine, printer and printer. and many more. The labeling work of the flat labeling machine can complete these purposes. After the labeling and packaging of the labeling machine, people can understand the product connotation through the label, which greatly facilitates people's lives. As a result of the unusual operation of the plane labeling machine, there are countless things. As a professional manufacturer of flat labeling machines, let us introduce the order of the correct operation of the plane labeling machine and pay attention to it!

1. Use the manual wheel to move the machine, and then confirm and adjust the correct position of each component.

2. Place glue and label: When placing the label, firstly put the label into a fan shape, and then put it into the label drive installation.

3. Start the power supply.

4. Affirm whether the air source pressure can be normal.

5. Press the vacuum pump switch.

6. Twist the jog/continuous change switch to the jog position while pressing the main unit switch. The glue is adhered to the fan-shaped rotating rod.

7. Place the product (bottle) on the belt.

8. The contact switch must be illuminated at the same time as the switch indicator light.

9. Twist the jog/continuous change switch to the continuous position and press the start of the main switch.

10. Be sure that the attachment is correct. If it is not ideal, stop the micro adjustment.

11. Check that the bottle and label enter the labeling time correctly.

12. The paper suction roller and the fan-shaped rotary lever are attached, and whether there is a strange sound when sticking.

Press and hold the spring piece on the side of the label's electric eye and slide it so that its center is at the distance between the two labels. Turn the intensity knob of the label's electric eye clockwise to the large size. At this time, the label's electric eye indicator light is on, then turn counterclockwise to the label. After the electric eye indicator light is turned off, add about 5 to 10 degrees and then slide the label electric eye back to the original position. Use your right hand to swing up and down a few times in front of the measuring object, so that the unprinted label between the labeling head and the printhead is peeled off, counted and recorded, and destroyed according to the label, clarification book storage and distribution procedures. Try to stick a few products, check the print position of the lot number and expiration date, and then adjust the position of the print: adjust the nut on the left side of the print head clockwise, the print position of the batch number and expiration date is shifted to the right, and the reverse movement is reversed.

When the flat labeling machine is temporarily idle, the power should be unplugged and covered with a dust-proof cloth to prevent dust from falling on the labeling machine. In addition, the high temperature belt of the labeling machine should also be decontaminated regularly, so as to better ensure the high quality operation of the labeling machine. Secondly, the flat labeling machine maintenance must not forget to apply a smooth oil. The labeling machine should apply a certain amount of smooth oil after a long period of operation. Many components in the labeling machine, such as gears, bearings and gearboxes, tend to rust and wear after a period of use. When smooth oil is applied, the components of the labeling machine can be smoothed. The requirement is to point out that the labeling machine should be coated with smooth oil after working continuously for more than 48 hours. The flat labeling machine should stop regular maintenance after a certain period of operation. On the one hand, it ensures that the labeling machine works well and can extend the life of the labeling machine.

Related News

- Talking about the use of automatic labeling machine

- What is a semi-automatic palletizer and its scope of use?

- What are the advantages of using an automatic sealing machine

- I'll show you how small labeling machines work.

- The application of automatic Palletizer is introduced in detail

- Do you know the labeling process and functional characteristics of the automatic labeling machine?

- Application of automatic planar labeling machine in tag

- What are the main functions and characteristics of semi-automatic filling Machine

- Do you know what the characteristics of the marking machine are?

贝立智能

贝立智能

浙公网安备 33011002012462号

浙公网安备 33011002012462号